Control Logic in Electrical Circuits: Simple Ladder Diagrams & Logic FunctionS.

Estimated reading time: 6 minutes

Thank you for reading this post, don't forget to subscribe!Control Logic in Electrical Circuits: A Visual Guide to Ladder Diagrams and Logic Functions

Understanding control logic is essential for anyone involved in electrical engineering, automation, or industrial maintenance. Whether you’re fixing a machine in a factory, programming a PLC, or simply curious about how circuits operate in everyday equipment, knowing how control logic works will save you time and help you solve problems with confidence.

Ladder diagrams and logic functions don’t have to be complicated. By breaking down symbols and functions step by step, you can gain insight into how electrical systems make decisions automatically or respond to manual input. Let’s explore the essentials and learn how to read, apply, and troubleshoot control logic in real-world circuits.

What Are Schematic and Ladder Diagrams?

Schematic diagrams use graphical symbols to show electrical connections and the flow of a circuit. They’re essential for making sense of how devices are wired and how current flows through a system.

A ladder diagram gets its name because the arrangement of lines and symbols looks like the rungs of a ladder. The vertical rails represent electrical supply lines, while the horizontal lines, or “rungs,” show the logical connections and devices like switches or relays. Ladder diagrams are a favorite in industry because they are easy to follow and directly show how systems operate.

For more details on how ladder diagrams are structured and why they’re so widely used, check out this in-depth guide on “Ladder” Diagrams and Control Logic.

Manual vs. Automatic Control: Making Sense of Switches

When analyzing a control circuit, the first question is often: Who or what controls the switch?

- Manually controlled switches require a person to push a button or flip a lever. Think of starting a motor by pressing a button.

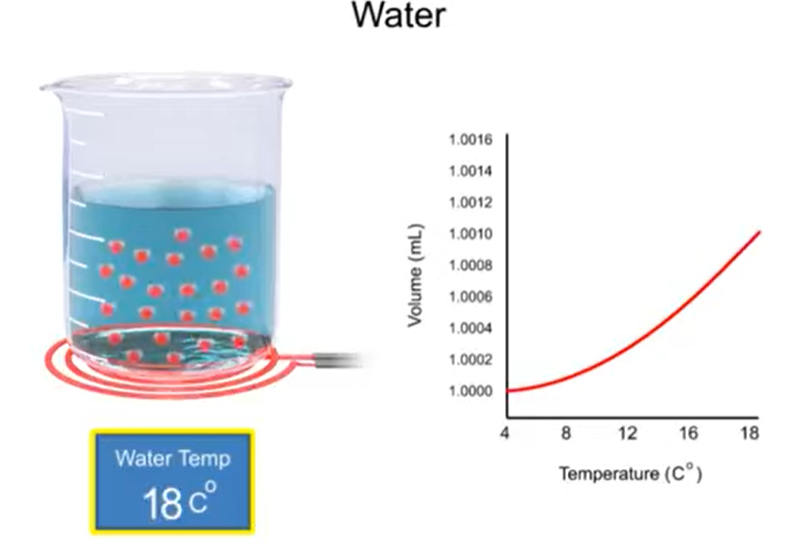

- Automatically controlled switches operate based on conditions in the environment, like temperature or liquid level, and don’t need human action.

Real-World Example: The Sump Pump

Imagine a pump that empties water from a tank. A float switch sits inside and reacts to water level:

- When the water rises, the float lifts and triggers the switch automatically.

- This “start” signal powers the pump until the level drops again.

This simple operation hides complex logic in the background, guiding not only water pumps but countless machines in factories and homes.

Understanding Control Logic: The Heart of Automation

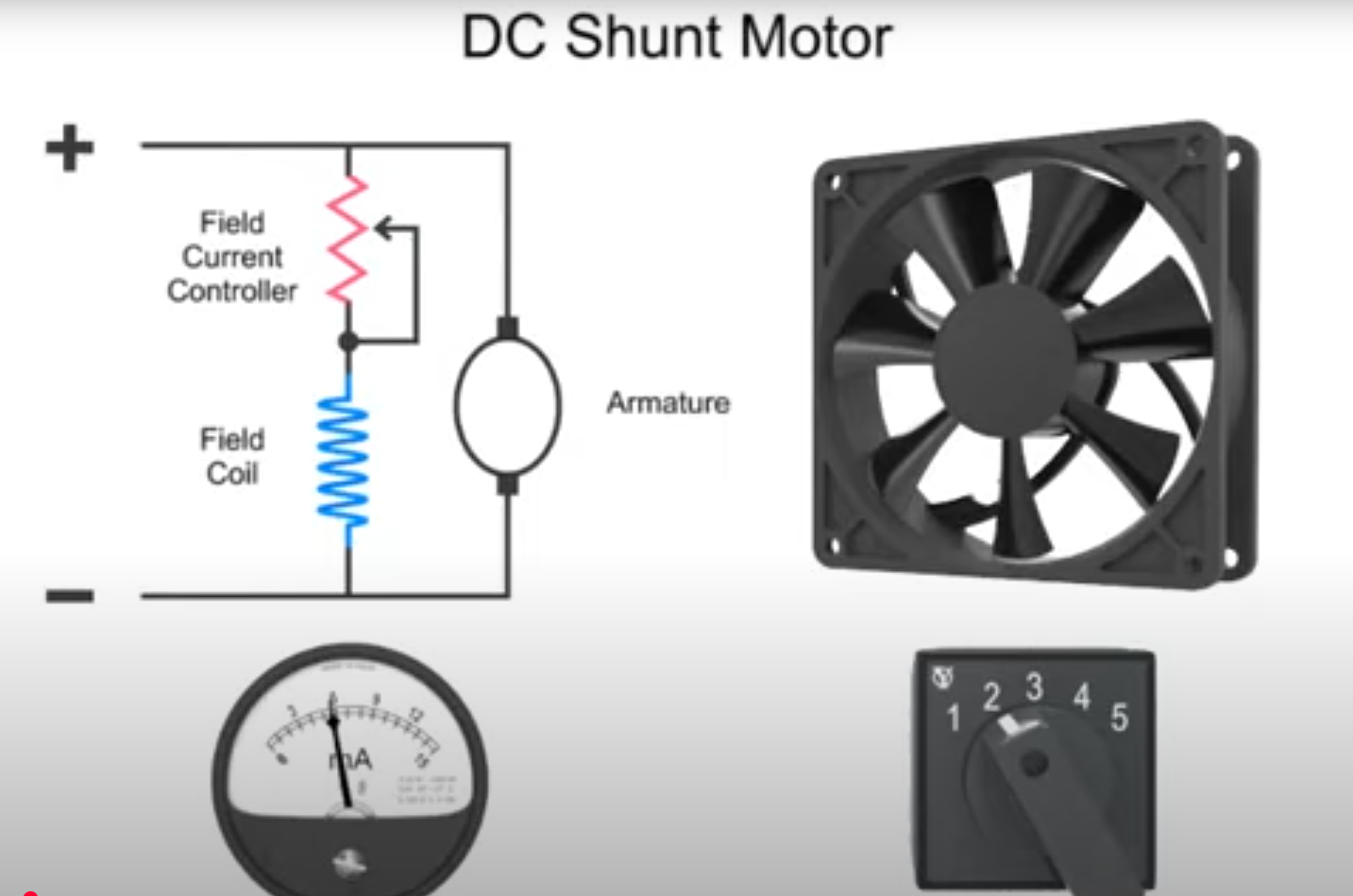

Control logic describes the rules for how electrical devices function together. By connecting push buttons, switches, and relays in different ways, you create systems that follow specific logical rules.

The main logic types found in control circuits are AND, OR, NOT, NOR, and “memory” or latching circuits. Let’s break these down, using plain language and easy-to-follow scenarios.

AND Logic: All Conditions Must Be True

AND logic asks for all switches in a path to be “on” (closed) before an output occurs. In ladder diagrams, this means placing switches in series on a rung.

Example:

Two automatic switches control a motor coil (M2):

- If both the float switch and a temperature switch are closed, the circuit completes and the motor starts.

- If either switch is open, nothing happens.

| Condition | Float Switch | Temp Switch | Motor Coil (M2) |

|---|---|---|---|

| Both switches closed | Closed | Closed | Energized |

| Any switch open | Open/Closed | Open | De-energized |

Learn more about how ladder logic applies AND rules in practical motor circuits in “Motor Control Circuits” from All About Circuits.

OR Logic: Any Condition is Enough

OR logic says that only one switch needs to be closed for the output to activate. On a ladder diagram, this is shown with switches arranged in parallel.

Example:

Two start push buttons can activate a motor coil (M1):

- Pressing either button completes the circuit and starts the motor.

- The circuit works even if only one is pressed.

This arrangement is handy anywhere you want to control a device from more than one location.

Memory (Latching) Logic: Keeping the Circuit “ON” After a Trigger

Some machines need to stay on, even after the button is released. That’s where memory logic—sometimes called latching—comes into play.

How it works:

- When you press a start button, the motor coil (M1) turns on.

- This action also closes an auxiliary contact (called M1), adding a parallel path around the start switch.

- Even after letting go of the button, current still flows, and the motor keeps running.

This smart design ensures you don’t need to hold the button the whole time.

Normally Closed Switches: Stopping and NOT Logic

Not all switches are designed to close a circuit. Normally Closed (NC) switches keep the circuit on by default and open the circuit to stop it.

NOT Logic: Turning OFF with an NC Switch

NOT logic uses a single NC switch, often a stop push button. The motor coil (M1) stays on until the button is pressed:

- Releasing the button: Circuit is closed, motor stays on.

- Pressing the button: Circuit opens, motor turns off.

NOR Logic: Any Stop Will Do

NOR logic takes NOT logic further by connecting two or more NC switches in series. Pressing any stop button breaks the circuit and turns the device off.

Example:

Two stop buttons in series, both NC:

- Pressing either opens the circuit, and the motor deactivates.

| Condition | Stop 1 | Stop 2 | Motor Coil (M1) |

|---|---|---|---|

| Both released | Closed | Closed | Energized |

| Either pressed | Open | Closed/Open | De-energized |

For a deep dive into these logic types and their real-life applications in ladder diagrams, see “Ladder Logic Basics”.

Why Control Logic Matters

Understanding these logical arrangements is key for anyone working with:

- Factory automation systems

- Building management controls

- Home automation

- HVAC and pump control panels

This knowledge helps you troubleshoot circuits faster, spot errors in wiring, and even design your own automation projects, from simple light switching to complex process lines.

If you’re looking to take your skills further and understand more advanced concepts in panel design and planning, the resource “Chapter 9 Planning the Panel” is a valuable next step.

Summary Table: Control Logic Arrangements

| Logic Type | Switch Arrangement | Action Needed | Result |

|---|---|---|---|

| AND | Series (NO) | All switches closed | Output energized |

| OR | Parallel (NO) | Any switch closed | Output energized |

| NOT | Single (NC) | Switch pressed (opened) | Output off |

| NOR | Series (NC) | Any switch pressed | Output off |

| Memory (Latch) | Parallel w/aux | Start closed; stays on | Output remains energized |

NO: Normally Open; NC: Normally Closed

Conclusion

Reading and designing control logic using ladder diagrams is like following a recipe—each ingredient (switch, button, relay) has a role, and the order matters. From starting pumps to running large motors and coordinating complex industrial tasks, these simple arrangements bring the world’s machinery to life.

Practice reading ladder diagrams and thinking through which logic you need for each job. Understanding these basics will help you solve problems, build smarter systems, and communicate clearly with other professionals.

For more insights and visual walkthroughs on control logic, you can check out detailed tutorials and examples from platforms like All About Circuits or RealPars.

Ready to dig deeper? Explore how these concepts appear in real industrial circuits and hands-on projects. You’ll find yourself recognizing logic patterns everywhere—from your home’s water tank to complex manufacturing robots.

Happy troubleshooting and circuit building!