DC Shunt Motor Guide 2025: Structure, Performance, and Top Industrial Uses

The DC Shunt Motor A Comprehensive

The DC Shunt Motor A Comprehensive

Estimated reading time: 5 minutes

Thank you for reading this post, don't forget to subscribe![embedyt] https://www.youtube.com/watch?v=PjgF0ipB32Q[/embedyt]

The DC Shunt Motor: A Comprehensive Guide

A DC shunt motor is a key choice when you need constant speed and dependable performance in machines. Its unique structure helps maintain speed under different loads, making it popular in industries where reliability is a must. This listicle covers the basics, structure, working, performance, advantages, and where you’ll see DC shunt motors in real use. Let’s break down everything you need to know.

1. What Is a DC Shunt Motor?

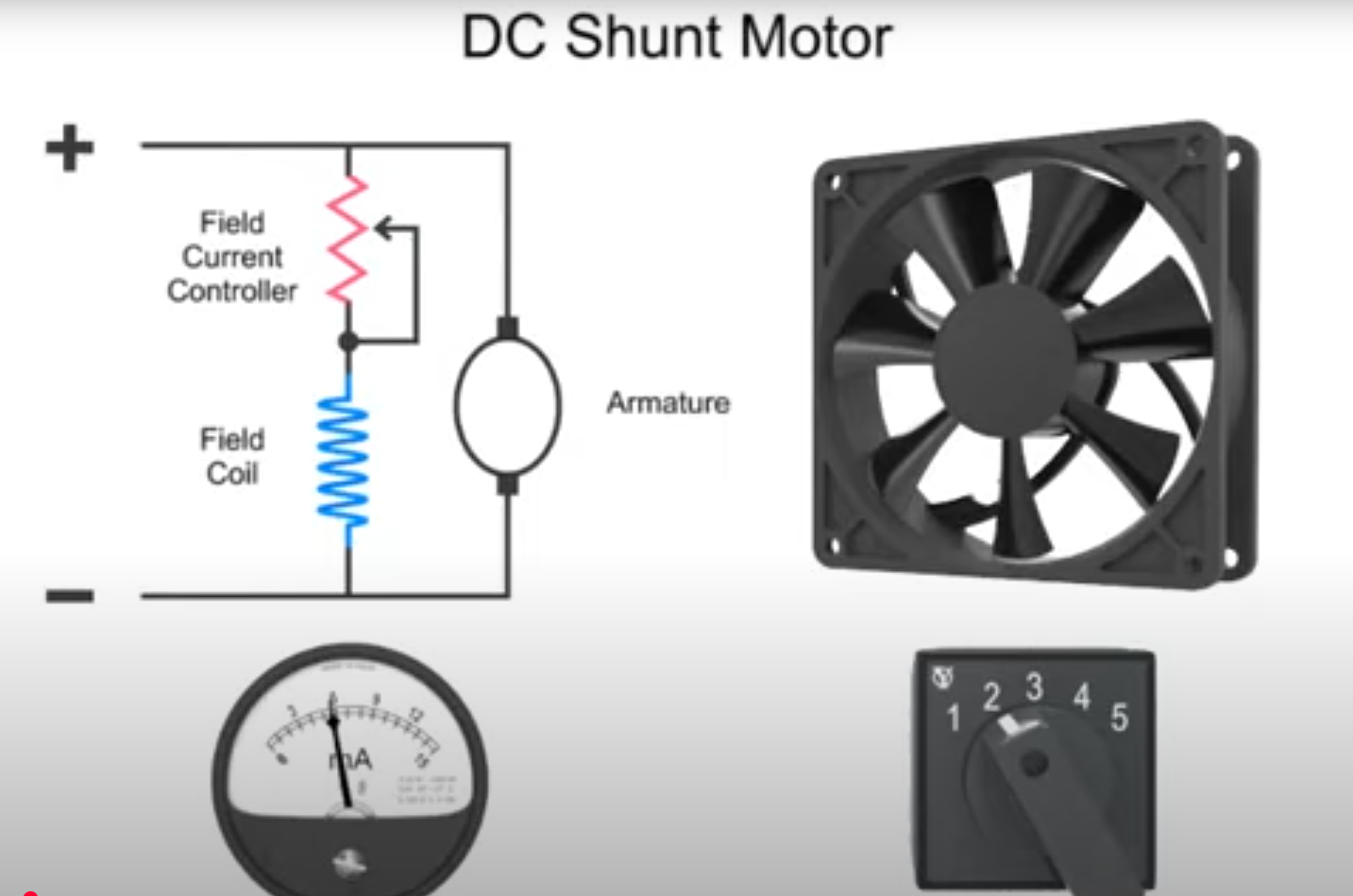

A DC shunt motor is a type of electric motor that runs on direct current (DC) power. Both the armature and the field windings are connected in parallel, also known as a “shunt.” This setup allows the motor to keep a steady speed regardless of the load. The shunt design gives the motor its ability to deliver a consistent performance over time. You can explore more about the basic definition and structure in this clear breakdown of DC shunt motors.

2. Construction and Key Parts

The DC shunt motor’s main parts include the armature, field windings, brushes, and commutator. The field windings connect parallel to the armature windings, creating the “shunt” path. This design helps the motor achieve its stable speed. The brushes help transfer current between the stationary and rotating parts. The commutator changes the direction of current in the armature, keeping the motor turning the right way. Each part is built to withstand long-run operations and makes maintenance straightforward.

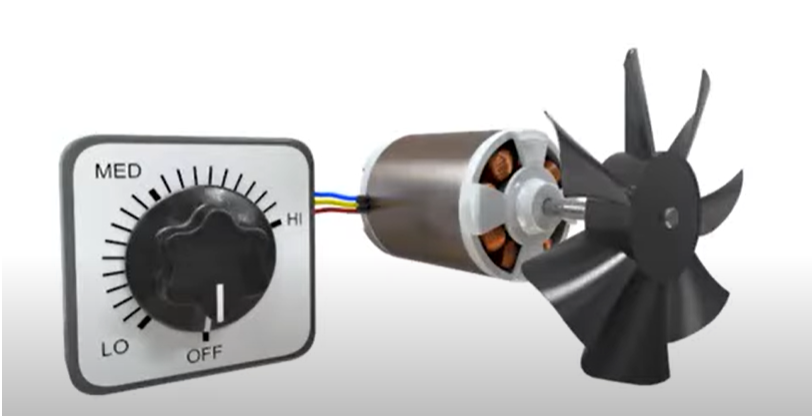

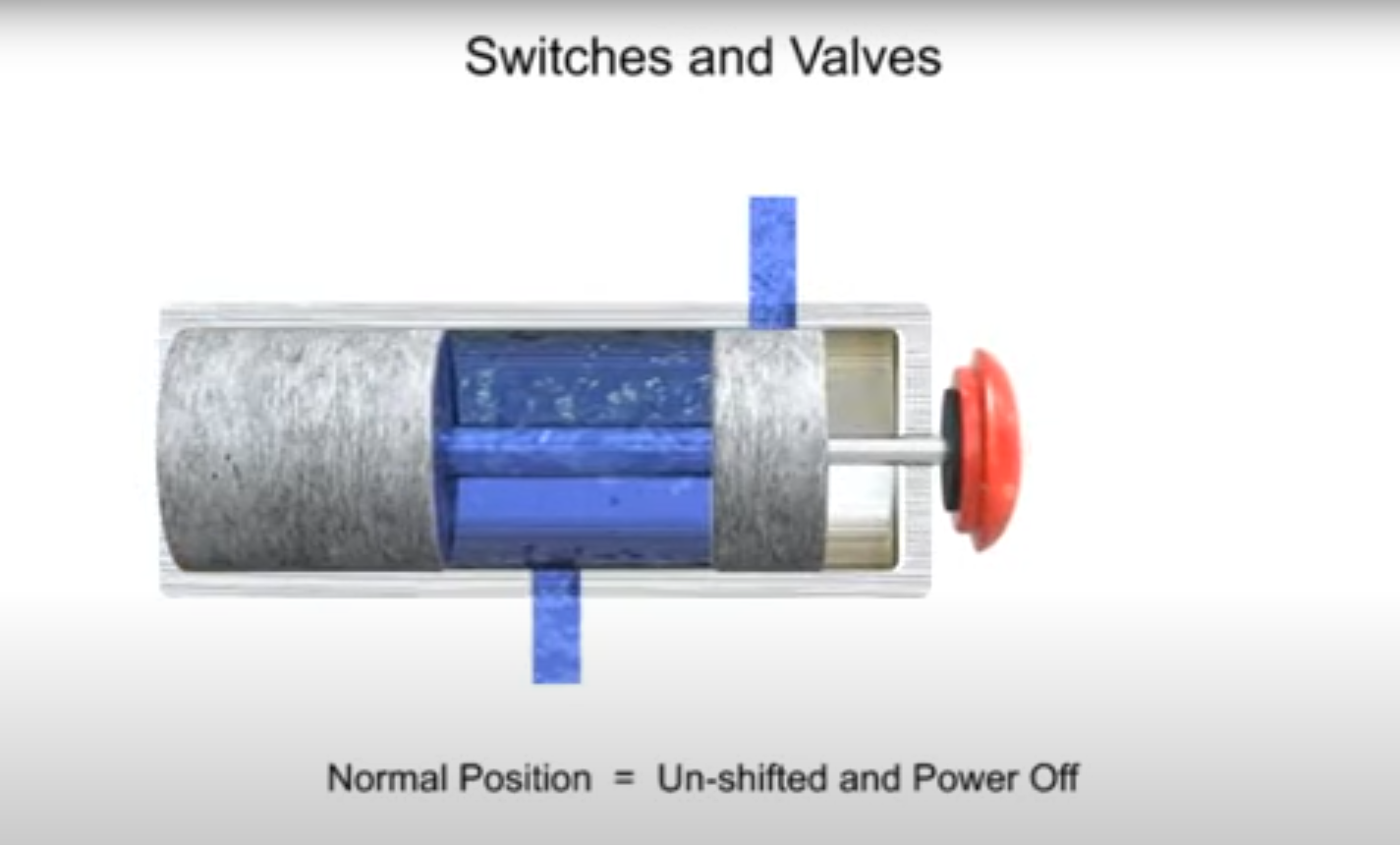

3. How a DC Shunt Motor Works

Once power flows into the motor, the parallel field and armature windings start their jobs. The shunt winding produces a magnetic field, while the armature creates movement. As the motor spins, the commutator and brushes keep the current moving smoothly. The result is a motor that won’t slow down much if you add extra load. This characteristic is a main reason engineers pick DC shunt motors for steady, continuous work. For a deeper technical look, see this guide on the operation and control of DC shunt motors.

4. DC Shunt Motors vs. Other DC Motors

DC shunt motors, series motors, and compound motors are the big three in DC motor design. While series motors give a strong start but poor speed control, shunt motors are famous for their predictable, steady output. Compound motors combine both designs for a balance, but the shunt motor stands out for uses where speed consistency is critical. This comparison is outlined in detail in this DC motors guide.

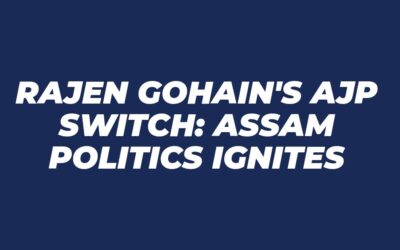

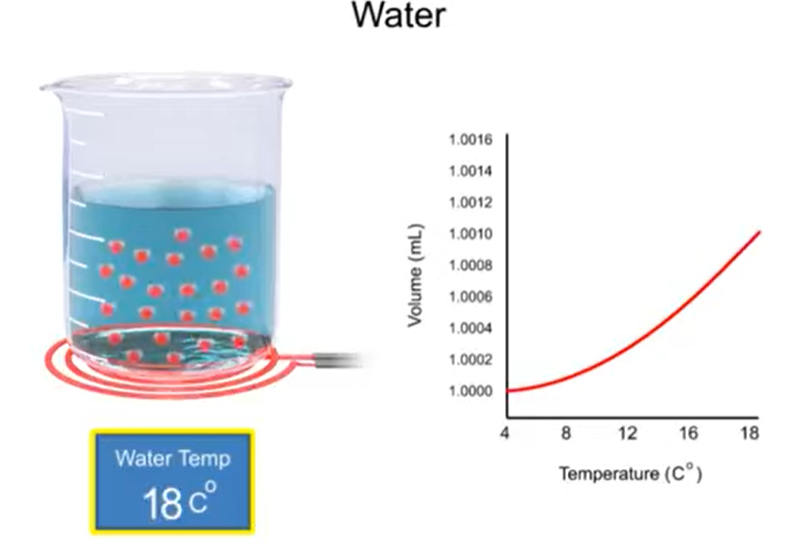

5. Performance and Speed Control

The biggest win for DC shunt motors is their speed regulation. As load increases, current in the armature increases, but the shunt field’s current stays almost unchanged. This balance is what makes the motor’s speed hardly change with load. For those needing fine speed control in tools, fans, and conveyors, this quality is a big draw. This performance holds up even in tough factory settings and long hours.

6. Main Advantages

DC shunt motors last long, don’t get damaged as easily by sudden load changes, and can run at consistent speeds. They’re simple to start and stop, and their design supports easy repairs. Their versatility means fewer headaches in wiring and installation, which is great for busy production floors. There’s a handy overview of their perks and best practices in this Shunt DC motors article.

7. Typical Applications

You’ll find DC shunt motors in conveyor belts, lathes, fans, blowers, and even in textile and paper mills. Any job that calls for stable speed over time is a good match. You may also see them in labs and testing setups, where reliable results matter. Small changes in speed can affect quality, and these motors help prevent that.

8. Maintenance and Common Issues

Keeping a DC shunt motor running smoothly is mostly about regular cleaning and checking the brushes and commutator. Because there are fewer high-stress parts than in other motors, breakdowns are rare. Common issues can include brush wear or dust buildup, but these are easy to handle if you stick to a simple maintenance plan.

9. Safety, Costs, and Extra Tips

DC shunt motors are designed for safety, but you should always follow standard guidelines for electrical systems. Make sure to disconnect power before inspection or work. In terms of cost, these motors land in the middle ground: not the cheapest, but their long-term value and minimal downtime often save you money in the long run. For extras on shunts and safe usage, this guide on DC shunts offers useful insight.

Conclusion

The DC shunt motor brings consistent, reliable speed to industrial settings, machines, and labs. Its parallel winding structure delivers steady results and makes it a practical option for many uses. With basic care, these motors have a long service life and are easy to maintain. When you need reliable, simple speed control, the DC shunt motor is hard to beat.

If you want to increase efficiency or reduce headaches in your workflow, understanding the fundamentals of these motors goes a long way. Explore trusted sources and keep learning for the best results in all your motor projects.