How to Control a DC Motor: Complete Guide to Drive Circuit Design and Speed Control

How to Control a DC Motor

How to Control a DC Motor

Estimated reading time: 5 minutes

Thank you for reading this post, don't forget to subscribe![embedyt] https://www.youtube.com/watch?v=JqoC2y3qF78[/embedyt]

How to Control a DC Motor: Complete Guide to Drive Circuit Design

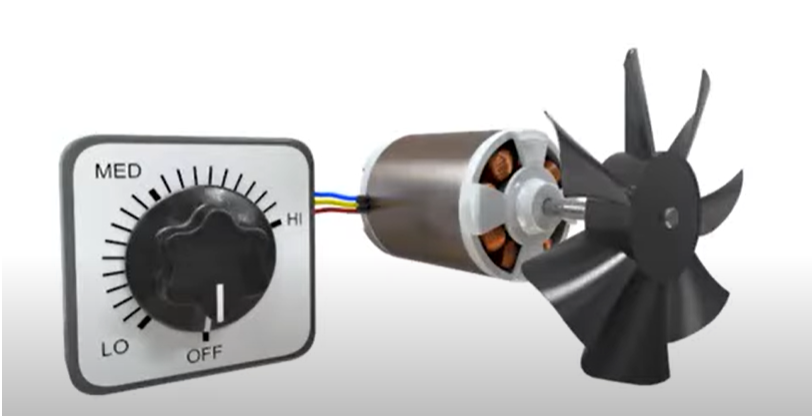

Controlling a DC motor seems simple, but creating an efficient and reliable drive circuit means understanding key electronic building blocks. Modern DC motor control goes far beyond just powering the wires. This guide explains how you can drive, control, and get the best performance from your DC motor every time.

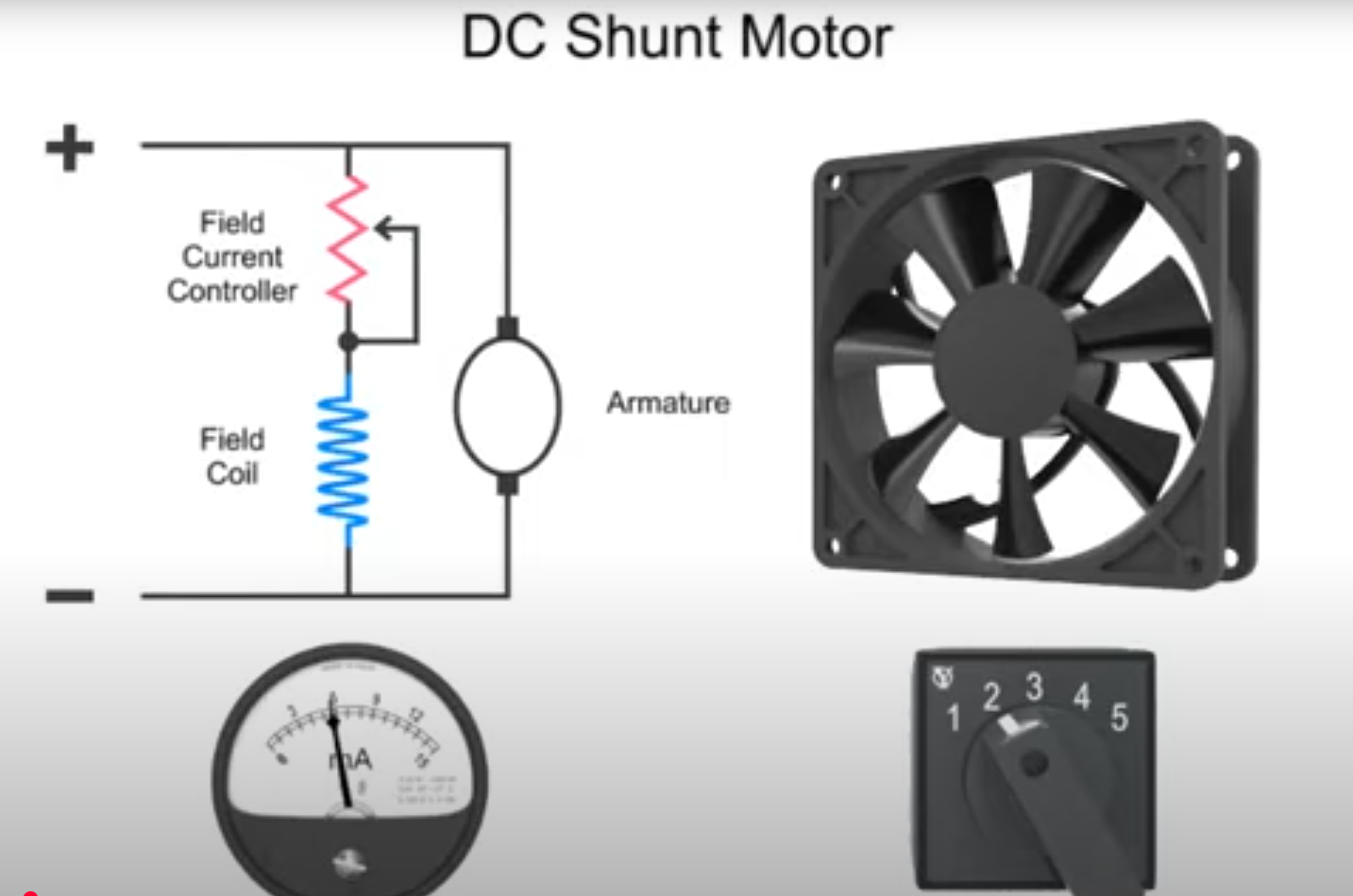

1. Know Your DC Motor

Understanding your motor is the first step before selecting a drive circuit. DC motors come in brushed and brushless types, each with different speed, torque, and wiring needs. For this guide, we’ll focus on basic brushed DC motors, common in robotics and DIY projects. These motors need a variable voltage source and a circuit to set their rotation direction and speed. If your motor’s datasheet lists stall current or voltage ratings, note them before connecting any drive electronics.

2. The Role of the H-Bridge

The H-bridge is the classic circuit used to control both the speed and direction of a DC motor. Arranged in an “H” shape with transistors or MOSFETs at the corners, this setup lets you reverse the current through the motor and change its direction at will. For a detailed look at design options, read the DC Motor Drive Circuit Design overview. H-bridges also allow for braking and coast functions, giving you precise movement control, as used in robots and remote-controlled vehicles.

3. Speed Control with PWM

Pulse Width Modulation (PWM) is a highly effective method to control how fast a DC motor spins. By rapidly switching the motor’s supply voltage on and off, PWM signals let you adjust the average voltage delivered, and therefore the motor speed. Lower duty cycles mean slower speed; higher duty cycles make the motor spin faster. This technique is essential, especially when paired with an H-bridge to allow for full forward and reverse speed adjustment. For examples and explanations, check out this article on How to Control the Speed and Direction of a DC Motor.

4. Implementing L298N and L293D Driver ICs

Pre-built driver chips like L298N and L293D take the complexity out of building a drive circuit. They offer dual H-bridge circuits, making them perfect for controlling one or more DC motors with straightforward wiring. Both chips accept logic signals from microcontrollers and can handle variable voltage (typically up to 36V for L298N, slightly less for L293D). The L298N Motor Driver tutorial details wiring, pin functions, and using PWM for speed control. Always check the datasheet for allowable current, as exceeding it will cause thermal shutdown or damage.

5. Direction Control

To reverse the motor, the H-bridge circuit (or a driver chip) switches the current flow through the motor. With chips like the L293D or L298N, you’ll set one input high and another low for forward, reverse the signals to swap direction, or set both low/high to stop. The Control DC Motors with L293D Motor Driver IC tutorial gives a hands-on walkthrough for common driver chips.

6. Safe Power Supply Connections

Driving DC motors directly from your microcontroller will not work, as most small boards can’t supply enough current for even small motors. Always use a separate, adequately rated power supply for your motors and connect the grounds of your control circuit and motor power supply together. Many driver modules include onboard voltage regulators for the logic circuits, but for higher supply voltages, you may need to power your controller separately.

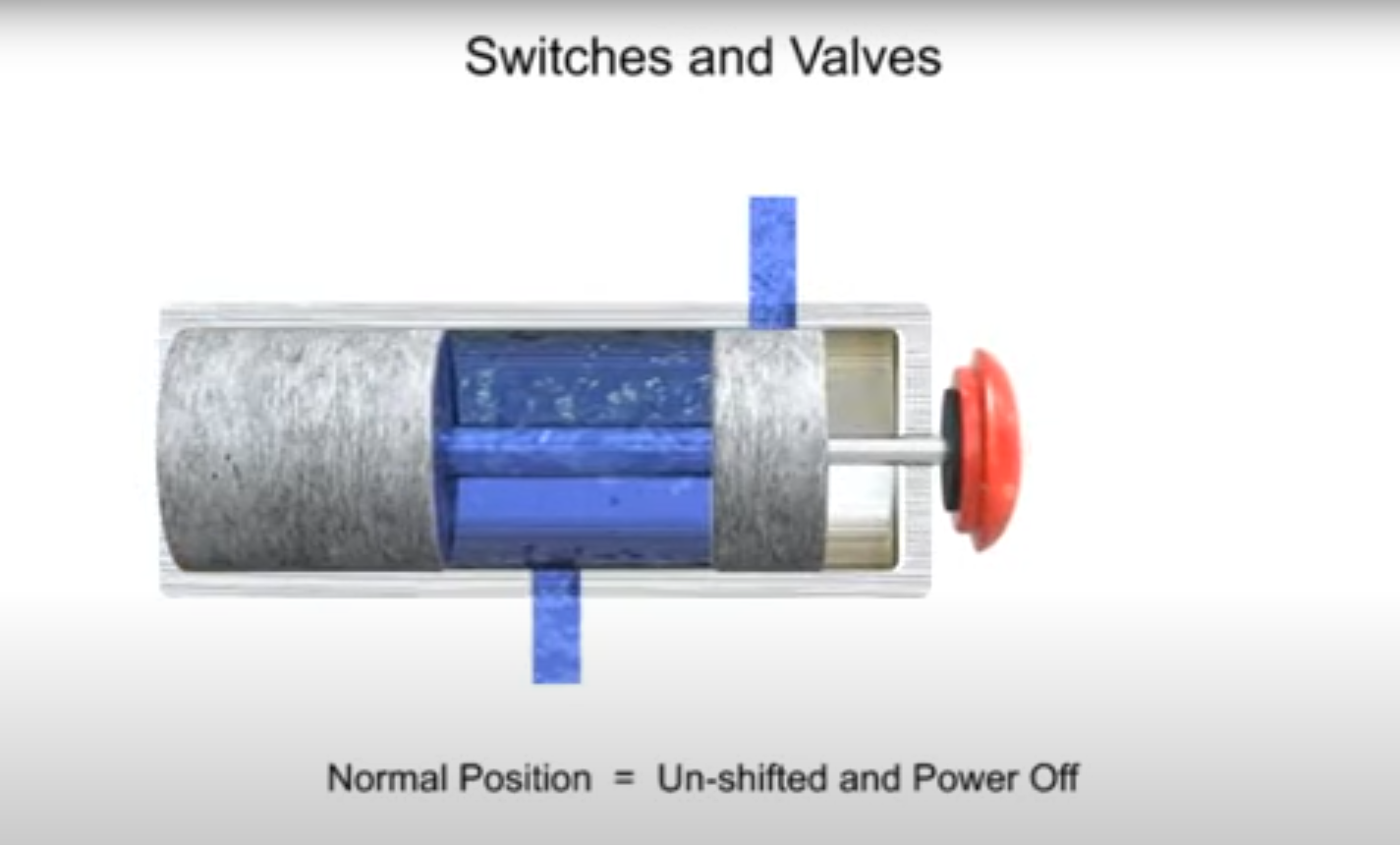

7. Wiring and Protection Components

Motors act as small generators when stopping or changing direction, so always include flyback diodes across the motor terminals (if your H-bridge or driver chip doesn’t have them built in). These diodes protect your circuit from voltage spikes. Also, consider using capacitors to filter out electrical noise and avoid logic glitches.

8. Integration With Microcontrollers

The real power comes from pairing your motor driver circuit with a microcontroller like an Arduino or Raspberry Pi Pico. Microcontrollers can output PWM signals to your driver chip’s enable pins and logic signals for direction control, just as shown in practical guides like Interface L298N DC Motor Driver Module with Arduino. Connect PWM-capable outputs to the driver enables, match logic outputs to direction inputs, and always share a common ground.

9. Testing and Troubleshooting

Once connected, test your drive circuit starting with a low duty cycle and short bursts. Listen for smooth acceleration without stalls or excessive noise. If the motor doesn’t start, increase the duty cycle; some motors require a minimum pulse width to overcome static friction. Keep an eye on chip temperatures and check for unexpected resets, which could signal a power mismatch or grounding issue.

10. Expand Functionality with Feedback

For advanced projects, sensors like encoders let you track motor speed and position. You can use this feedback to automate stopping points, maintain consistent velocity, or integrate closed-loop speed control.

Conclusion

Driving a DC motor reliably means more than just hooking up some wires. Think through your motor choice, use a suitable H-bridge or driver chip, add protection, and connect everything correctly to your controller. Combine PWM speed control and direction pins for flexible, precise movement. To get started, you can follow in-depth examples using L298N driver modules and Arduino.

Well-designed drive circuits keep motors performing at their best while protecting your electronics. With the right setup, you’ll achieve fast, safe, and smooth control for any DC motor project.