pH Control Guide: Accurate Measurement for Water, Industry, and Aquariums

Estimated reading time: 8 minutes

Thank you for reading this post, don't forget to subscribe!Mastering pH Control: The Science Behind Accurate Measurement for Water, Industry, and Fish Tanks

Keeping pH levels where you want them matters more than most people think. Whether you run a factory, clean your water, or just want happy fish in your tank, staying on top of pH can be the difference between success and a mess. This guide covers why pH is important, how to measure and control it, and real-world tricks you can use—even if you’re just starting out.

What Is pH and Why Does It Matter?

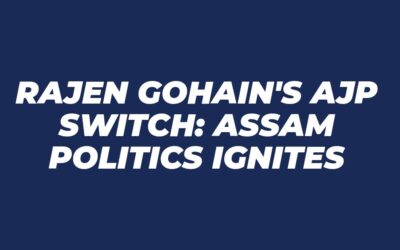

Understanding pH starts with its definition. pH measures how acidic or alkaline a solution is. It works on a scale from 0 to 14. A value of 7 means neutral, below 7 means acidic, and above 7 means alkaline. This number packs a lot of punch in testing the quality and safety of substances.

Where Is pH Control Needed?

Being able to control pH opens up a world of benefits across many fields. You probably see its fingerprints in:

- Food processing: Controls taste, texture, and shelf life.

- Wastewater treatment: Ensures water is safe before it heads back into the environment.

- Chemical manufacturing: Keeps reactions under control and products up to standard.

No matter the industry, a wrong pH level can spell disaster. Too much acid or alkaline content alters chemical reactions, spoils products, or puts safety at risk for people and equipment.

Why Is Correct pH Critical?

It’s not just numbers; the right pH:

- Boosts product quality. Bread tastes better, water is safer, and chemicals react as planned.

- Protects health. Out-of-range pH can harm skin, eyes, or, for fish, even their lives.

- Cuts costs by avoiding waste and damage.

- Keeps machines running smoothly, since extreme pH can corrode parts or clog valves.

How We Measure and Adjust pH

What Role Do pH Sensors Play?

A pH sensor is your eyes in the tank or line. It tests the pH of a solution in real time, sending readings straight to your controller. This sensor acts as a feedback device—it compares actual pH to your target or set point so you always know where you stand.

How Do We Adjust pH With Reagents?

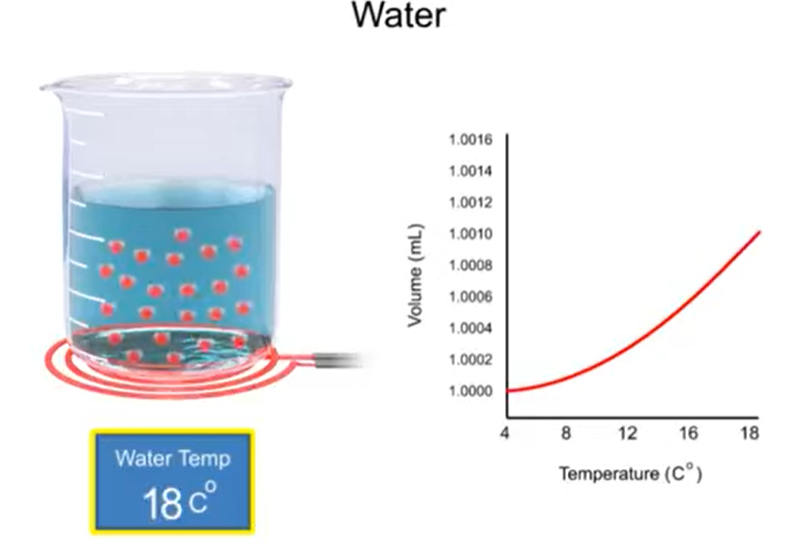

Getting pH where it belongs usually means adding something called a reagent. In this context, reagents are chemicals like acids or bases used to shift pH up or down:

- Add an acid to lower pH if things are too alkaline.

- Add a base to raise pH if things are too acidic.

Simple, right? Not quite. Because the pH scale is logarithmic, a small dash of reagent can have a big impact, especially at higher or lower pH values. This makes it tricky to dose just the right amount.

Why Is Dosing pH So Challenging?

Here’s where things get more complex:

- The effect of a single dose depends on the starting pH.

- The reaction isn’t linear; each whole step represents a tenfold change.

- Overdosing can swing your pH too far in the other direction.

- The process may keep changing as more solution flows in or out.

Key challenges in dosing:

- Small dosing errors make a big difference because of the logarithmic nature of the pH scale.

- Real-world reactions are rarely instant or perfect, so you need continuous monitoring.

- Different solutions react differently to the same dose.

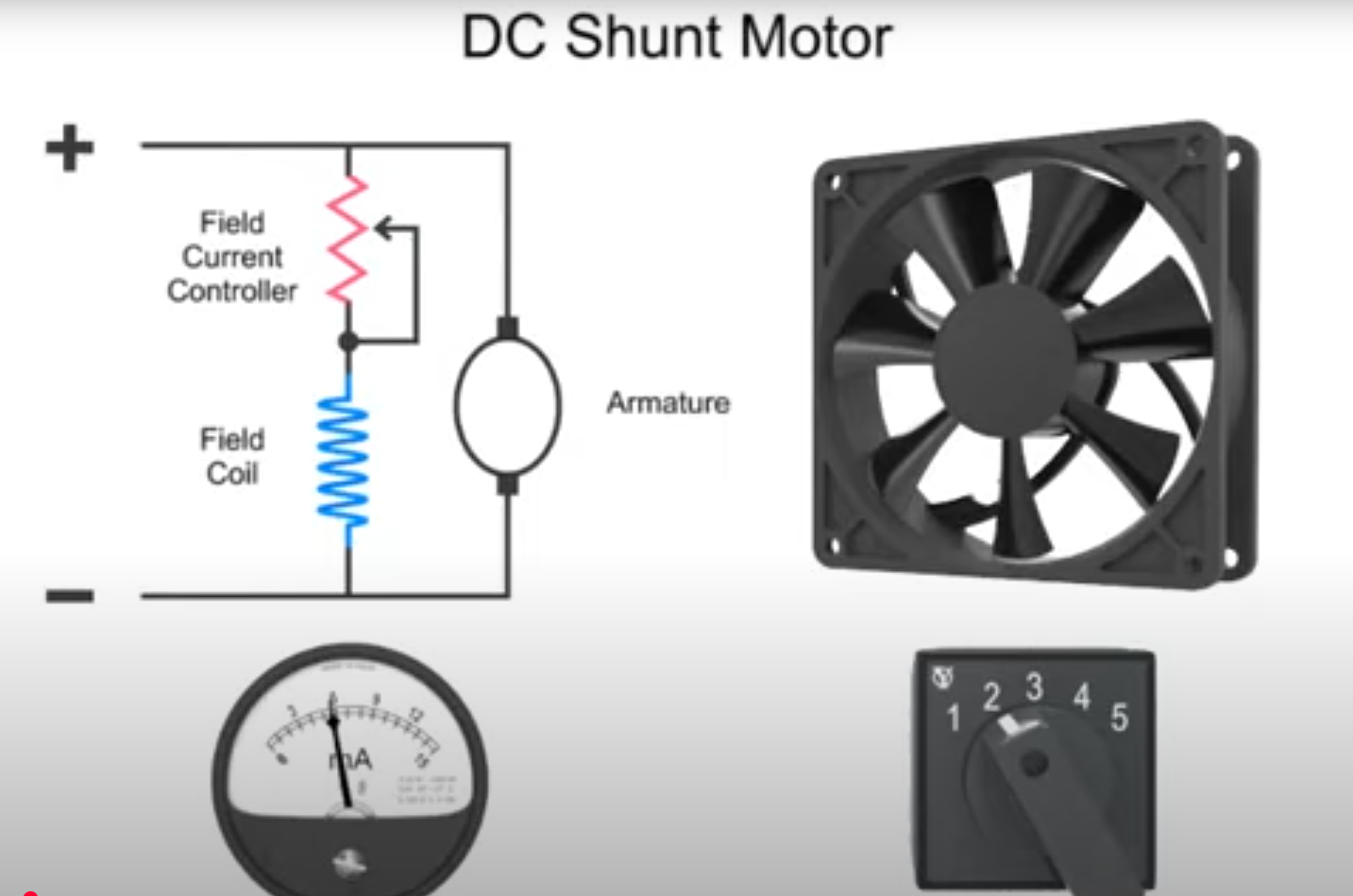

How Closed-Loop Control Keeps pH On Target

What Is a Closed-Loop Control System?

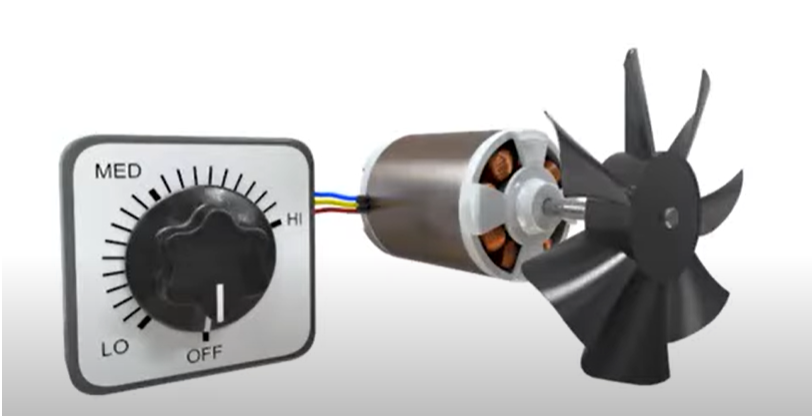

A closed-loop control system works like a thermostat, but for pH. It measures, compares, and adjusts—all in real time, all day long. This system takes the guesswork out of pH control and keeps process conditions steady.

Step-by-Step: How It Works

- Monitoring: The sensor measures current pH in the system.

- Comparison: The controller checks if the pH matches the set point (your target).

- Signal: If they don’t match, the controller sends a command.

- Reagent Dosing: A valve or pump adds acid or base to push pH back toward the target.

- Adjustment: Dosing rate changes based on ongoing measurements.

- Continuous Feedback: The system repeats this cycle endlessly.

Closed-loop control keeps you in the optimal pH zone, minimizing wild swings and costly mistakes.

Sample Control Flow

- Sensor reads high pH (e.g. 11)

- Controller calculates the difference from the set point (e.g. aiming for 9)

- Controller tells valve: “Open wider, add more acid or CO2”

- As pH drops and nears the set point, the system eases off the dosing to avoid overshoot

- Sensor continues to check pH, repeating as needed

Benefits You Can Count On

- More stable process output

- Less waste from overcorrection

- Swifter response to changes in the solution makeup

- Peace of mind with hands-off operation

pH Control in Action: Water Treatment with Carbon Dioxide

Want to see pH control in the wild? Let’s look at a common water treatment example using lime softened water.

System Goals and Setup

The goal is to keep water at a pH of 9, making it safe for discharge and perfect for certain uses. This is done with carbon dioxide (CO2) acting as the reagent to lower pH levels.

The Process Step-by-Step

- Influent Water Enters: Raw water flows into a treatment tank.

- Continuous Monitoring: A pH sensor tracks the level in the tank at all times.

- Feedback Loop: The sensor sends real-time data to the control panel.

- Comparison to Set Point: The controller checks current pH against the target (9).

- Control Valve Activation: If pH is too high (say, 11), the controller opens a valve to let in more CO2.

- Reagent Mixing: As CO2 mixes into the water, it reacts and gradually lowers the pH.

- Adjust and Repeat: As soon as the pH hits 9, the controller dials back the CO2 flow.

- Effluent Discharge: Treated water (now at the right pH) flows out of the tank.

Process Steps for pH Control in Water Treatment:

- Incoming water flows into tanks

- pH sensor measures and reports

- Controller receives feedback, compares to set point

- If pH is outside range, controller signals valve to add CO2

- CO2 mixes and lowers pH in a controlled fashion

- Sensor monitors; controller adjusts reagent flow as needed

- Treated water leaves tank, ready for final use or discharge

This cycle runs continuously, balancing inflow, sensor feedback, and reagent dosing to keep pH within spec. It’s smart, precise, and designed to stop problems before they start.

Interested in learning more about water treatment and pH control systems? Explore the SilverShieldTrading YouTube channel for more walkthroughs and experiments.

Small Scale, Big Results: pH Control in Your Fish Tank

You don’t need an industrial setup to care about pH. Aquarium owners face many of the same challenges—only on a smaller scale.

Why pH Control Matters for Aquariums

Fish and plants need a stable pH to thrive. Wild swings can lead to stress, illness, or even loss of your favorite swimmers. You want your tank to mimic natural waters, and that means keeping tabs on pH every day.

Practical Steps for Home Aquariums

Key Tools and Tips:

- Use a pH sensor or test kit for daily checks.

- Adjust pH using commercial acids or bases (check with an aquarium shop for safe products).

- Always add reagents slowly, with plenty of mixing time.

- Monitor for at least a few hours after every correction.

Top tips for safe pH control in fish tanks:

- Test regularly, not just when something looks off.

- Never add a large dose of reagent at once—split it up and retest between additions.

- Keep track of your results to spot patterns and avoid surprises.

- If possible, automate with a sensor and dosing pump for hands-off stability.

Closed-loop systems like those found in industry can work for hobbyists too. Automated controllers and continuous sensors are getting more affordable, giving you peace of mind and happier fish.

Want to Learn More? Stay Connected

If you’re interested in more smart tips and guides about pH, water treatment, or industrial controls, you’ll find plenty of useful updates at these spots:

- SilverShieldTrading Website: Tutorials, news, and product info.

- Facebook: SilverShieldTrading: Daily updates and discussions.

- YouTube Channel: sstrading-services: Videos on pH control, water treatment, and more.

- WhatsApp Contact for SilverShieldTrading: Questions about products or services? Reach out directly.

- SilverShieldTrading LinkedIn: Professional networking and company insights.

Bookmark your favorites or subscribe to keep up with the newest tricks, demos, and science behind water and chemical control.

Bringing It All Together

Getting pH right makes life easier, products safer, and water cleaner—no matter the size of your setup. The same science that keeps factories running can help you manage a home aquarium. Using pH sensors, careful dosing of reagents, and closed-loop control keeps your processes running smoothly.

Stay connected for more tips, and remember: whether you’re treating a city’s water or just caring for your fish, every pH point counts.