Proportional Gain vs Proportional Band Guide: Control System Basics.

Proportional Gain vs Proportional Band Guide: Control System Basics.

Proportional Gain vs Proportional Band Guide: Control System Basics.

Estimated reading time: 7 minutes

Thank you for reading this post, don't forget to subscribe!Proportional Gain vs Proportional Band: A Practical Guide to Control Systems

Anyone working with industrial automation, process control, or even home automation has likely heard about closed loop systems. Central to these systems are the controllers that keep things running smoothly, like maintaining the right temperature, fluid level, or pressure. Two important concepts often discussed are proportional gain and proportional band. These terms might sound intimidating, but they’re easier to grasp than you might think.

In this guide, you’ll explore what proportional gain and proportional band mean, see how they show up in real-world systems, and get practical ideas for applying them. By the end, you’ll know how to identify and use these concepts for better and more reliable control.

What Is a Closed Loop Control System?

A closed loop control system automatically adjusts its output to reach and maintain a desired condition or setpoint. For example, imagine a thermostat that controls your home’s furnace. The controller (the thermostat) continues to adjust the heating so that the room temperature matches your preferred setting.

A simple example used in engineering education is regulating the fluid level in a tank—a scenario you’ll return to shortly.

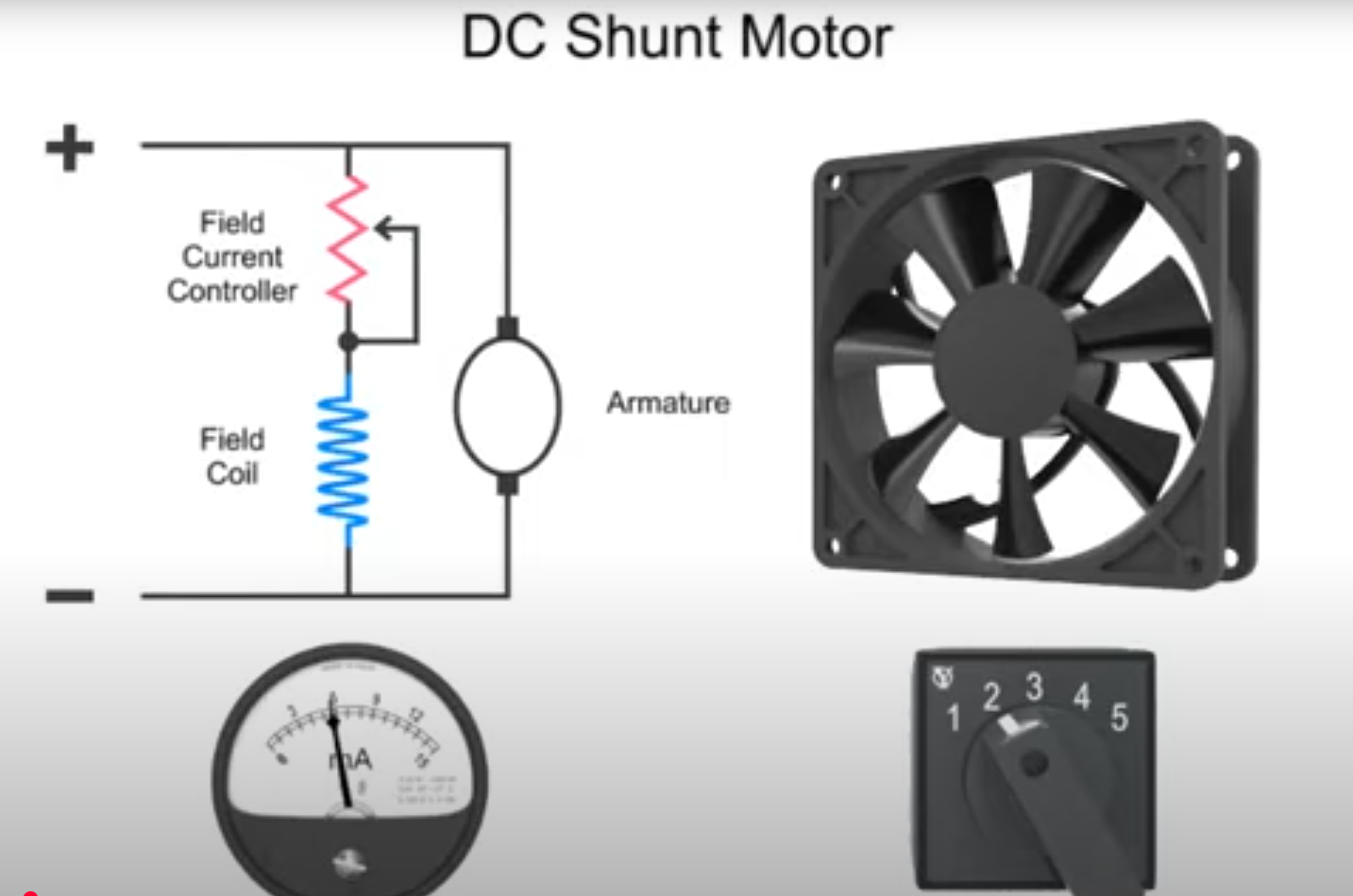

Key Components of Closed Loop Systems

- Input: The value you want to maintain (like a specific fluid level).

- Sensor: Measures the process variable (current tank level).

- Controller: Compares the input to the measured value and determines the needed output adjustment.

- Final Control Element: The device that acts on the physical process (like a control valve).

Proportional Gain: How Strongly Does Your System React?

Proportional gain is about how much the controller’s output changes compared to a change in the system’s input. It’s expressed as the ratio between the change in output and the change in input.

Defining Proportional Gain

Proportional Gain (Kp):

Kp = (Change in output) / (Change in input)

For example, if moving the process variable by 25% causes the controller to respond by changing the output 25%, the gain (Kp) is 1. If the output changes by 50% for the same 25% input change, the gain is 2.

Visualizing Proportional Gain: A Tank Example

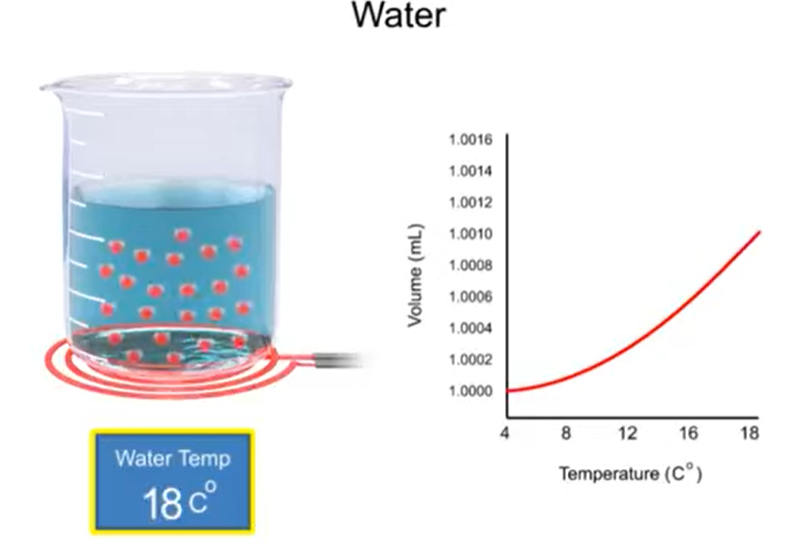

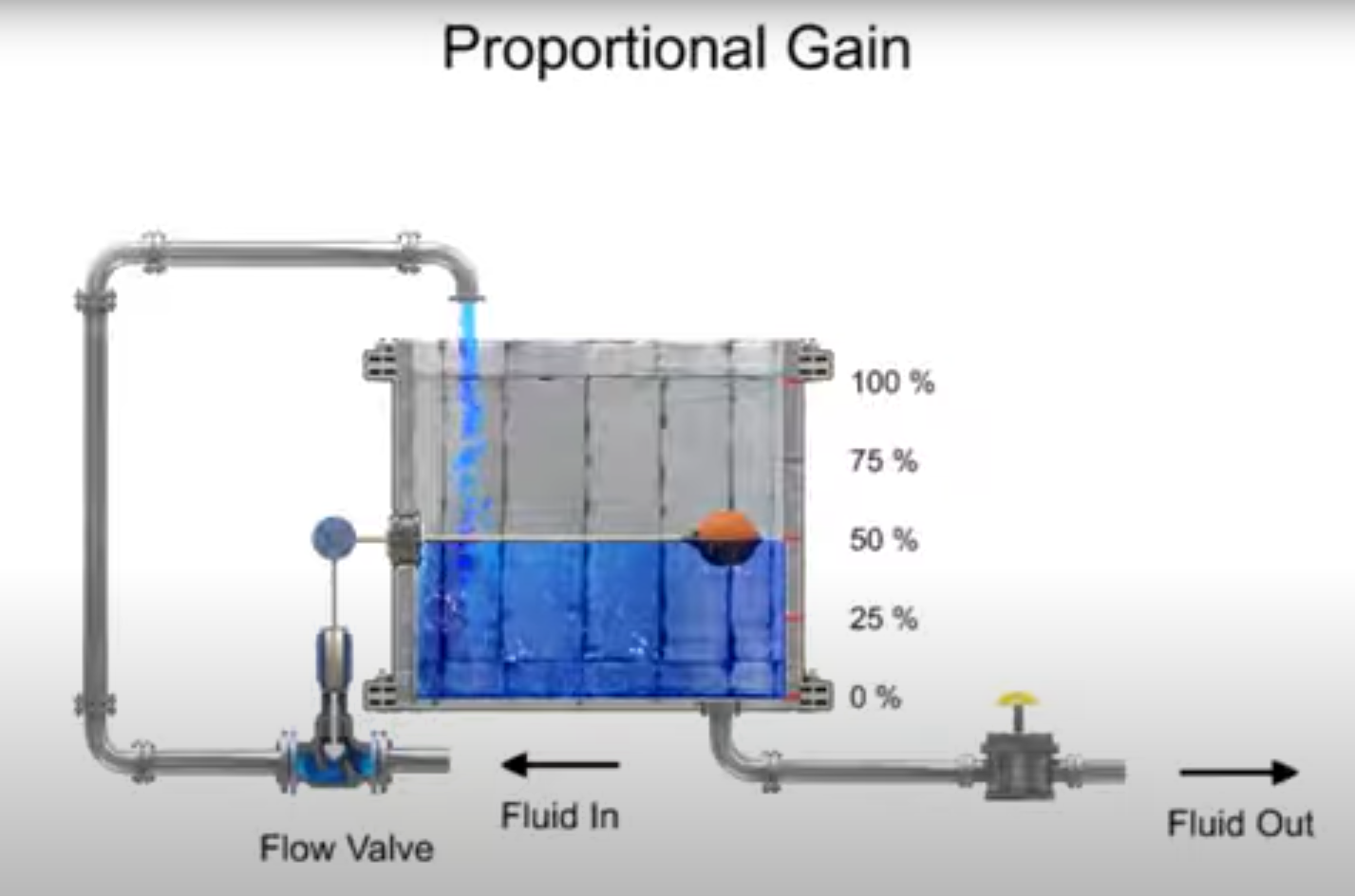

Consider a tank with a float attached to a valve. When the tank level drops, the float moves, causing the valve to open further and allow more fluid in. The system strives to keep the inflow and outflow balanced.

Example: Gain of 1

- When the tank is half full, the inflow equals the outflow.

- If the drain valve is opened more (increasing demand), the tank level drops by 25%.

- The float drops by 25%, and the control valve opens by the same amount.

- Result: A 25% change in input yields a 25% output change. Gain = 1.

Example: Gain of 2

- The float’s pivot point is moved, making the system twice as sensitive.

- Now, a 12.5% drop in tank level causes the valve to open 25%.

- Result: A 12.5% input change results in a 25% output change. Gain = 2.

This means higher gain leads to more aggressive changes in the system output for the same change in input.

For a more technical breakdown and real-world scenarios, Proportional Gain and Proportional Band Explained gives concrete examples you can check out.

Proportional Band: The Range for Full Action

While proportional gain describes sensitivity, proportional band expresses the range of change in the input needed to drive the output from one extreme to the other.

Defining Proportional Band

Proportional Band (PB):

The proportional band is the percentage change in the process variable (input) needed to move the final control element (output) through its entire operating range.

[ PB = (Change in controlled variable) / (Change in final control element) \times 100 ]

Proportional Band and Gain: Two Sides of the Same Coin

Proportional gain and proportional band are mathematically related. In fact, proportional band is the reciprocal of proportional gain, often expressed as a percentage:

[ PB = 100 / Kp ]

So, if you know one, you can always figure out the other.

Refer to this in-depth guide to Basic Control Theory for deeper mathematical links and classic examples.

Proportional Band in Action: More Tank Insights

Suppose the float is located at the very end of its arm, so it travels the full tank height. In this setup, the tank level must change 100% (from empty to full) to move the valve through its full opening range. Here, the proportional band is wide, and the system has low gain.

If you reposition the float to the center, it only takes a 12.5% level change for the valve to move through a quarter of its range. That halves the proportional band, doubling the system’s gain and making it more sensitive.

Proportional Gain vs. Proportional Band: Compare and Contrast

Understanding the tradeoff between proportional gain and proportional band helps you design or troubleshoot real systems. Here’s how they match up:

| Feature | Proportional Gain | Proportional Band |

|---|---|---|

| What it measures | Output response to input | Input change for full output |

| Sensitivity | Higher gain = more sensitive | Narrower band = more sensitive |

| Stability Risk | Too high can cause oscillation | Too narrow can cause hunting |

| Formula | Kp = Output/Input | PB = 100/Kp |

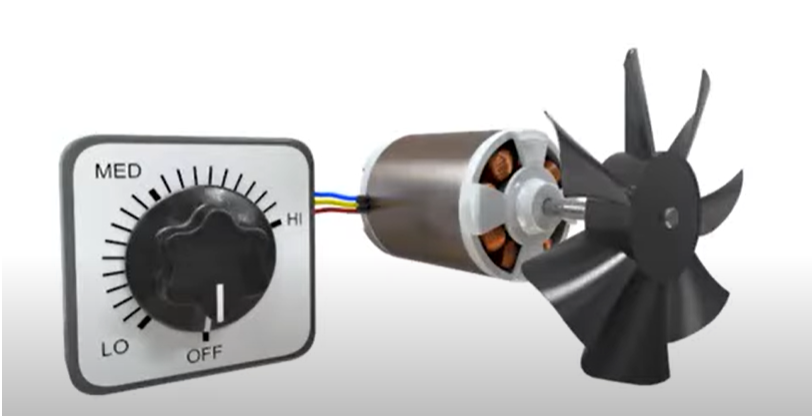

Tuning Your System: Why These Settings Matter

Balancing proportional gain and proportional band is crucial. Too much gain (or too small a band) can make your system overshoot or oscillate, like a shower that alternates between scalding and freezing. Too little gain (or too wide a band) leads to sluggish, unresponsive control.

So, every engineer must consider the needs of the process, the potential for sudden changes, and safety requirements.

Find deeper coverage and advanced strategies in resources like the Fundamentals of PID Control.

Practical Example: Float and Valve Mechanism

Let’s revisit the tank, float, and valve system for a hands-on illustration:

- Float at End: The tank must empty or fill completely (100%) for the valve to move fully. The system reacts slowly to small changes; it’s stable but slow.

- Float Midway: The system is more responsive; only a mild drop in level moves the valve significantly. There’s a risk of overcorrection if the setting is too aggressive.

Key Takeaways from This Example

- Proportional gain tells you how hard the system reacts.

- Proportional band describes how much process change is needed to max out the response.

Both need to be chosen to match the physical system’s requirements and performance expectations.

Common Problems and How to Avoid Them

- Oscillation: Too much gain or too narrow a band can cause the system to cycle or “hunt,” never quite settling.

- Lagging: Too little gain or too wide a band may make the system take too long to stabilize.

- Instability: A poorly tuned controller can respond too fast, then too slow, failing to hold your setpoint at all.

One solution is to start with moderate gain and band, then adjust incrementally. Watching system reactions in real time (safely, of course) helps find the sweet spot for both parameters.

Conclusion

Proportional gain and proportional band are key elements for controlling everything from factory lines to water tanks. They each describe a different aspect of how a controller manages change: gain tells you how strongly the system fights error, and band shows the range over which it works. Getting these settings right keeps processes safe, efficient, and stable.

Want to keep learning about process control or find more practical guides? Take a look at this clear explanation of Proportional Gain and Proportional Band for more detail.

For updates and more control system tips, you can follow Silver Shield Trading on Facebook or their LinkedIn profile.

Spend a little time exploring these simple parameters, and your next control project will run smoother and safer—every time.